our means

|

|

|

- 6500 m2 of shopfloor

- 400 m2 of office

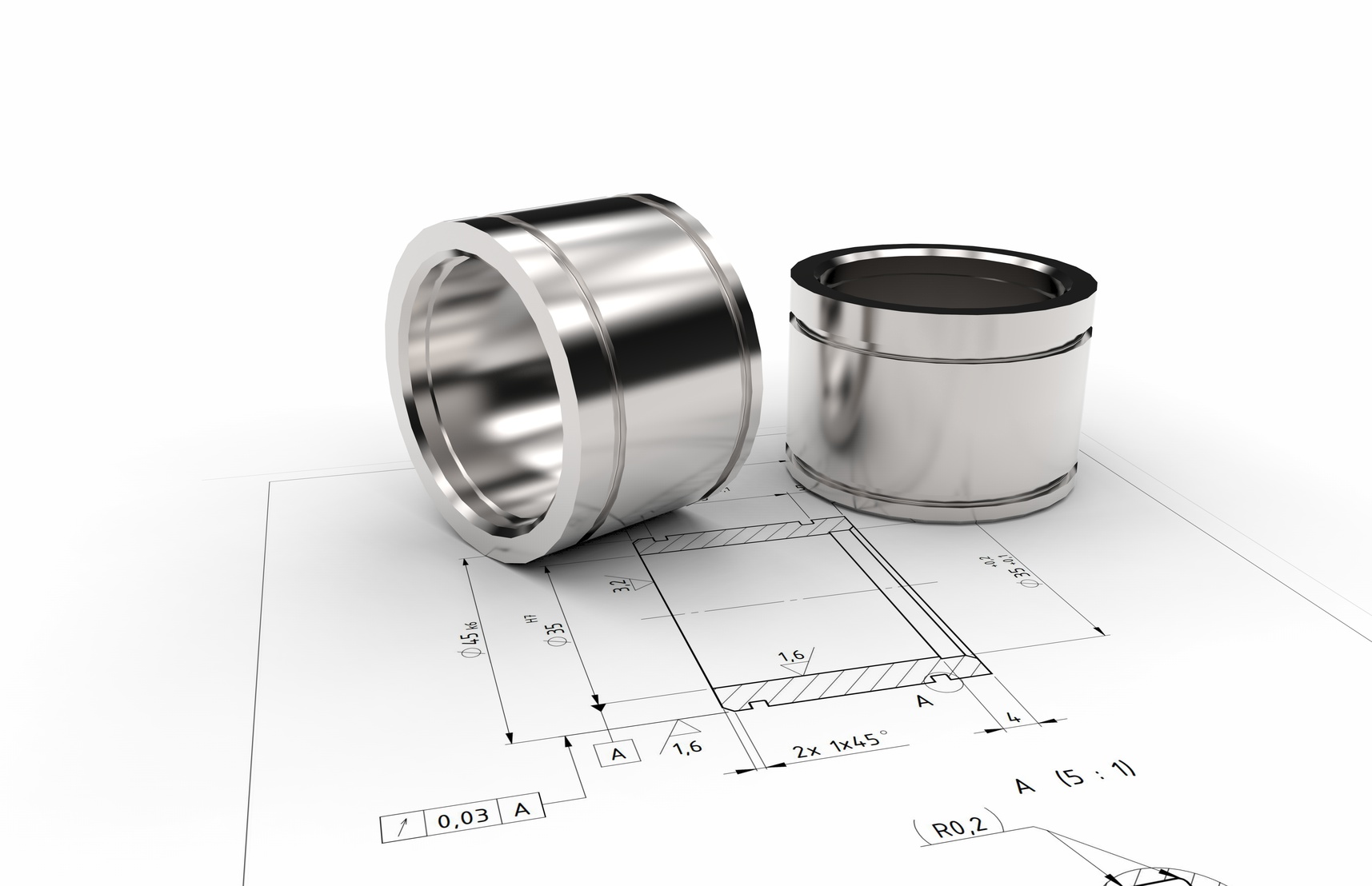

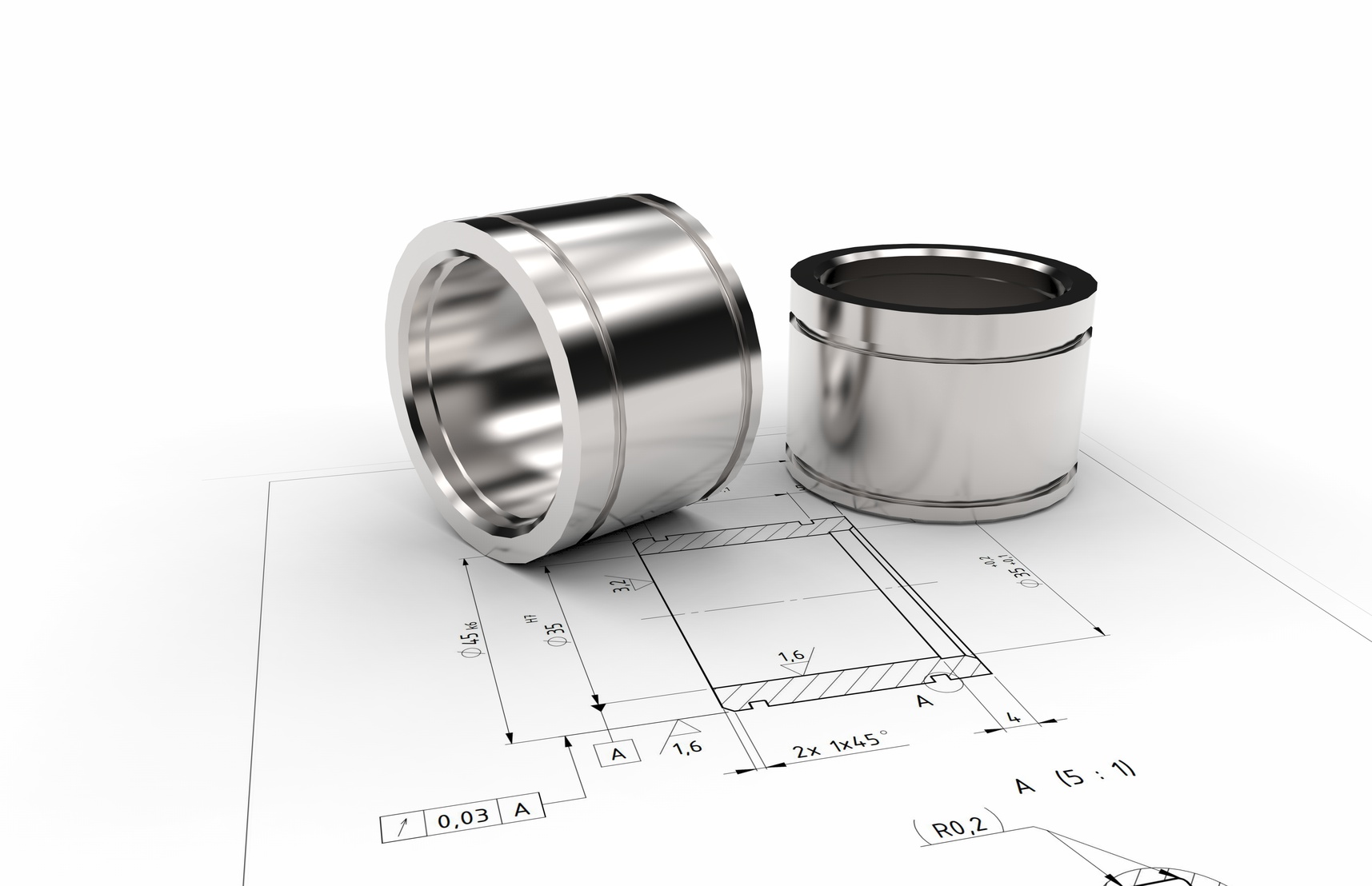

MAIN PRODUCTION EQUIPMENT:

- 11 Lathes with barfeeder (sliding headstock and twin spindle twin turret: Tornos, Tsugami, Nakamura)

- 20 CN lathes (Doosan, Nakamura) large capacity

- 9 Horizontal machining centers 4 axes (Doosan, Matsuura, Makino)

- 6 Vertical machinig centers 3, 4 and 5 axes (Matsuura, Doosan)

- 2 grinding machines (cylindrical, centerless).

- Wire cutting machine

- Welding station (TIG, MIG).

- 3 automatic sawing machines

- 5 conventional machines

- Shot-blasting, lapping, tribofinishing

- Treatment facility (gas nitrocarburizing).

CONTROL MEANS :

- 1 Three-dimensional machine

- 1 FARO arm

- Ultrasound / Hardeness control

HANDLING and lifting :

- Overhead crane 5 T

- Hoists : until 1,5 T

IT tools :

- CLIPPER

- TOP SOLID